The Transbay Tube turns 50: The groundbreaking history and future of the Bay's underwater crossing

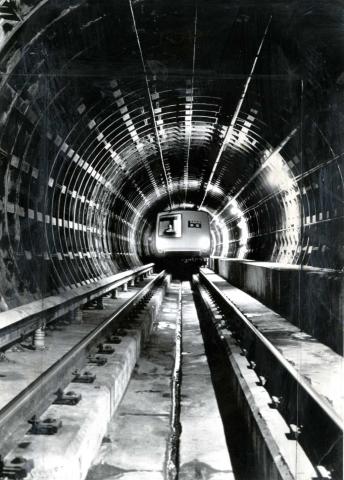

An Engineering Marvel: "Nobody has a tube like ours"

September 16, 1974, was a banner day in the history of the Bay Area. On this day, 50 years ago, BART’s Transbay Tube opened for passenger service.

The 3.6-mile-long Tube was unlike anything the world had ever seen. At the time, it was the longest immersed tube in the world, a title it held until 2010, and it mystified the public, who were mesmerized by the idea of a miles-long structure sitting 135 feet below the water’s surface. To some, it was a preposterous notion – train rides under the ocean?!? -- but the nonbelievers quickly hushed on that fateful day in 1974. They, too, wanted to take an underwater voyage from Oakland to San Francisco.

This is the story of a modern marvel – its past, present, and future. It is also a story about people – those who ushered the Tube into existence and those who are still working to ensure it stands for generations to come. Long after all of us have departed this earth, the Tube will remain.

On the Transbay Tube’s 50th anniversary, BART honors this one-of-a-kind structure that has ferried millions of passengers across the Bay for five decades and will continue to do so for decades to come. In the above video, we invite you to look inside the engineering opus for yourself.

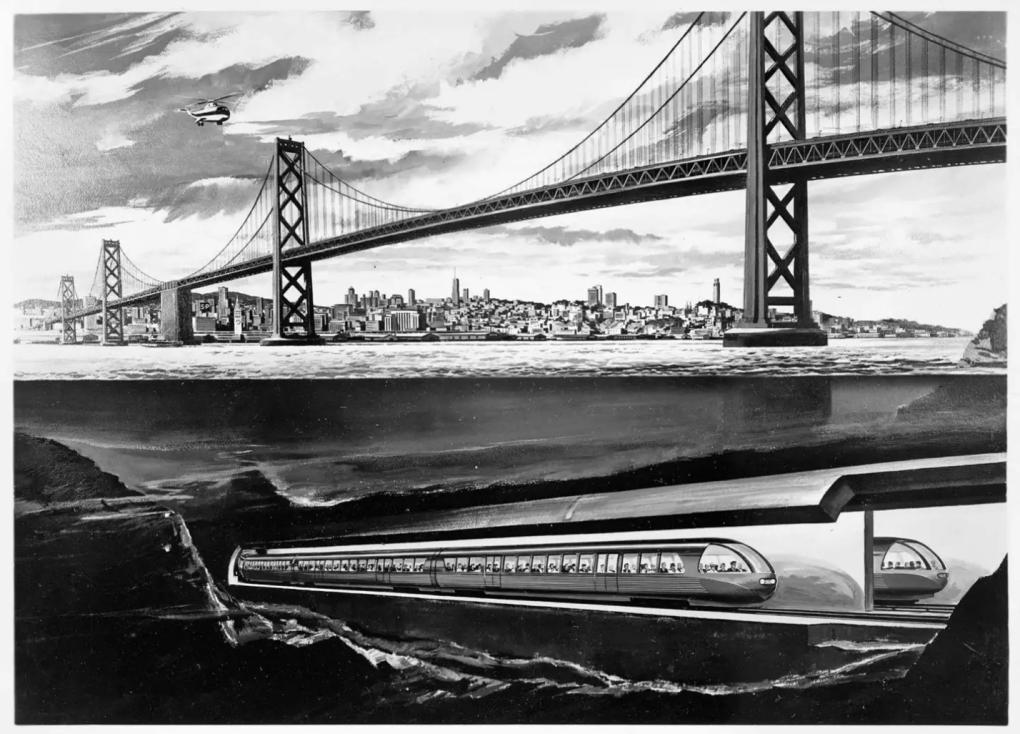

1961: The first concept drawing of the Transbay Tube.

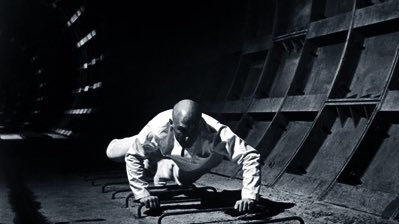

It was 1973 when budding actor Kenny Meyers got a job power washing the Tube to prepare it for its public debut. After that first gig with BART, Meyers never left. He retired from BART after 48 years in 2021.

Meyers still remembers showing up to that first interview in a suit and tie, not totally sure what position he had applied for. He needed a job and didn’t care much what it entailed.

“During the interview, the supervisor asked one question: ‘Do you have jeans?” Meyers remembered. “When I nodded, he said, ‘Great. Wear ‘em tomorrow and show up here at this time.’”

Meyers did as he was told, and after a month as a utility worker, he was sent to the Tube with a fellow worker and a 300-foot hose. Their task: wash the dusty walls before the structure’s premiere.

"At the time, I didn’t know anything about the project,” said Meyers. “We were looking at each other going, what is this thing? At 20 years old, it was an eye-opening experience. That’s when I realized how crazy engineering is.”

Not many people have had the chance to see the Tube where it lay – only specially trained divers who can navigate the zero-visibility waters and perhaps the ghosts of long-ago shipwrecks. It’s not just mud and muck down there, though there is plenty of that. There are waves of sand – not unlike the dunes on land – deep holes, and huge mounds of rock. Sharks, whales, porpoises, fish – all the creatures that call the Bay home – float above this feat of engineering that sits 135 feet below the surface at its maximum depth.

It’s another world down there, and it’s in this world one is zooming through at 70 miles per hour when riding a BART train from Oakland to San Francisco.

Most of us aren't paying a lot of attention when we make this familiar voyage. We’ve got things to do, phones to scroll, books to read. The exception may be the many generations of children mesmerized by the quick trip through the ocean’s depths, their eyes glued to the windows in the hopes of seeing a leopard shark or a playful seal.

The Tube isn’t translucent, and if it were, you wouldn’t see anything that deep in the water anyways. But in 1974, not long after the Tube opened, Meyers wanted to make a couple of kids’ day.

Various Transbay Tube mementos are pictured.

He got his chance one afternoon when a train came to a halt right in front of a vent in the upper gallery of the Tube, where Meyers happened to be standing.

“I pushed my face right up to the vent and made a face like I was swimming,” he said. “The kids screamed! They really thought I was swimming down there.”

Back when the Tube first opened, Meyers said people thought of it like Disneyland’s Monorail or its submarine ride, where you look out the windows and see all the animatronic mermaids and fish flapping around.

“People would ride it like they were at an amusement park, just for fun,” Meyers said. “It was one of a kind! It was over the top!”

“There's nothing really down there, though. No Starbucks or anything,” Meyers clarified. “Maybe I should push for that...”

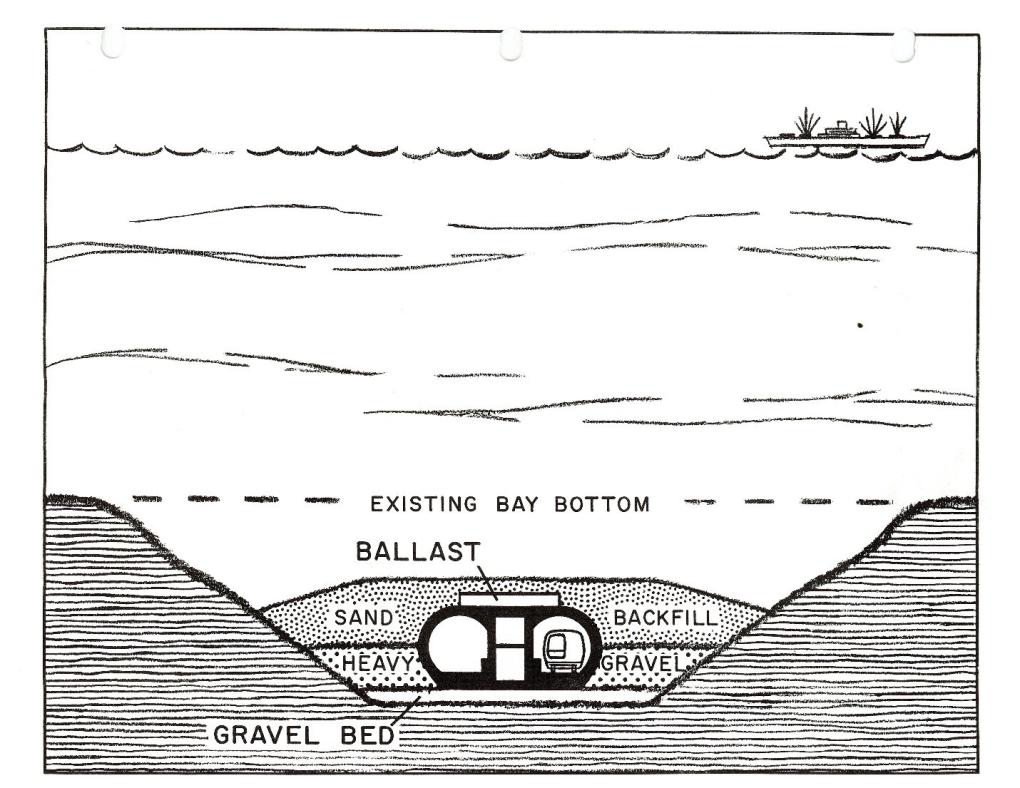

A drawing of the cross-section of the Tube in the San Francisco Bay.

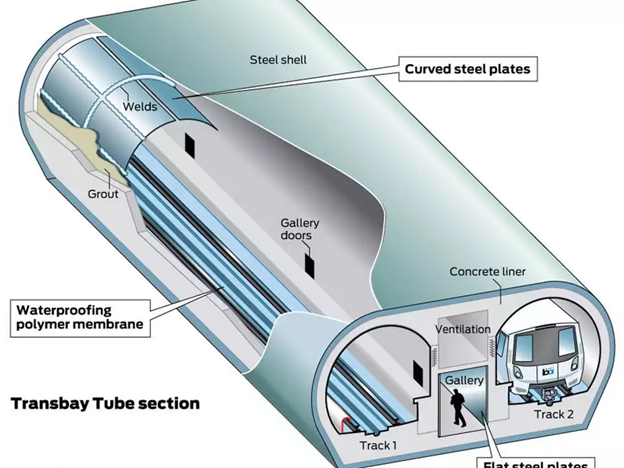

The diagram of the Tube is pretty simple when it comes down to it (at least it looks that way). There are two bores, each with one trackway. Trains move west from West Oakland Station through the right bore (when looking from Oakland) and east from Embarcadero Station through the left bore. It’s not visually dissimilar to a giant pair of super long-lensed binoculars.

Between the bores there is an upper gallery and a lower gallery for pedestrian access, ventilation, and utilities. Workers use the galleries to get around the Tube, as evidenced by Meyer’s prank, sometimes on specialized vehicles that are akin to narrow golf carts. There are also bicycles on hand in case a cart loses its charge. Or you can make the trek back to land by foot.

BART staff enter the tube via five-story vent structures located on either end. Once you descend, you either start walking, cycling, or hitch a ride on a cart. There’s nowhere to go but through or back where you came from.

What’s it like down there? Pretty dark, for one, and despite cleanings, it’s a bit grimy thanks to all the brake dust from the trains. It’s also blustery due to fans that are constantly circulating air – you better be hanging onto your baseball cap if you get too close.

Then there’s the motion of the trains coming in and out. “When the trains come through, there’s wind blasting through the cracks of the gallery doors,” Meyers said. “Once it leaves, there’s a suction effect. A train in a Tube is not unlike a piston.”

Meyers added that the Tube has a very specific smell that he can’t quite place his finger on. “But after I get out of there, I’d smell like it for a week.”

The Tube isn’t a Disney creation, but there's magic inside, especially when you’re zooming through in the front cab or the very end of a train. In the latter scenario, thanks to the glow of the brake lights, you feel like you’re passing through giant scarlet smoke rings, bigger than any talking caterpillar could blow, as you move through each of the structure’s 57 segments.

By the way, Kenny Meyers isn't the only actor whose hung around the Tube. In 1971 while the structure was still being built, George Lucas filmed a scene for his first feature film, THX 1138. In the film, Robert Duvall is shown climbing "up" from the subterranean Orwellian world, but he's actually crawling horizontally through the Tube. The structure has also appeared in Predator 2, Eve of Destruction, Eye for an Eye, The Shannara Chronicles, and an episode of Nash Bridges, among others. Its sounds were even in the videogame Dead Space.

I. An Underwater Bay Crossing is Born

With zero fictional embellishments, the Tube is as fantastic as something Ray Bradbury or Philip K. Dick might envision. So, we’re left with the question: How did BART bring this crazy thing from the realm of imagination into the realm of reality?

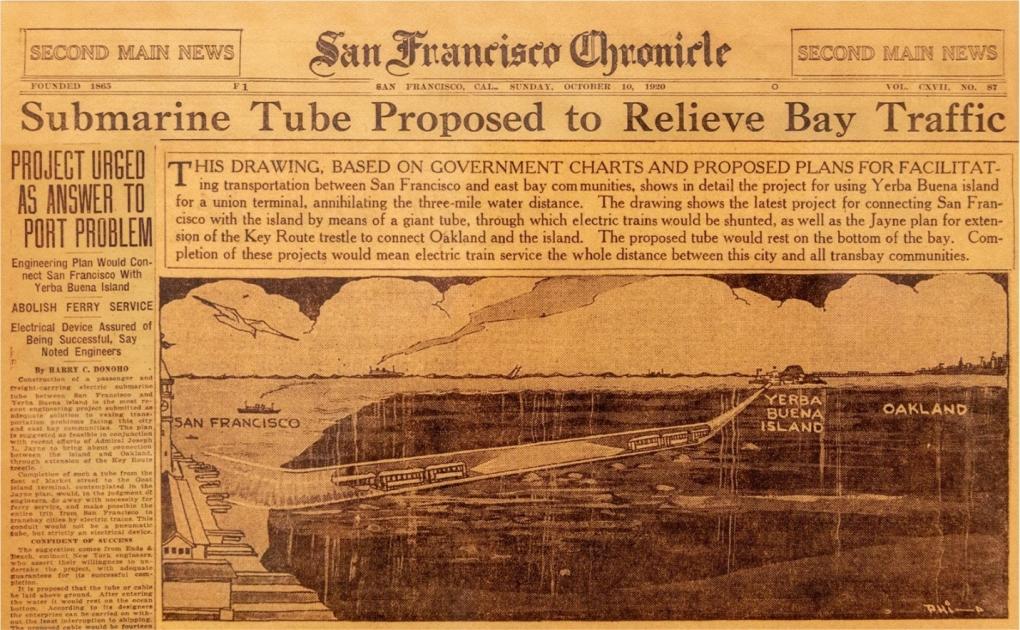

You could say it started with San Francisco’s beloved eccentric Emperor Norton. In 1872, the man who proclaimed himself “Emperor of the United States” issued a proclamation proposing the idea of an underwater rail tunnel that would cross the San Francisco Bay. A few months later, he made another proclamation threatening to arrest Oakland and San Francisco leaders who rudely ignored his initial request.

“Believing Oakland Point to be the proper and only point of communication from this side of the Bay to San Francisco, we, Norton I, Dei gratia Emperor of the United States and Protector of Mexico, do hereby command the cities of Oakland and San Francisco to make an appropriation for paying the expense of a survey to determine the practicability of a tunnel under water; and if found practicable, that said tunnel be forthwith built for a railroad communication.”

- Emperor Norton’s Tunnel Proclamation of May 12, 1872

Fast forward to 1947, and Emperor Norton’s grand designs were finally being put into play. That was the year a joint Army-Navy Commission issued their recommendation for an underwater Tube to relieve traffic congestion on the ten-year-old Bay Bridge. Even then traffic was terrible, despite the relief provided by Key System streetcars that ran on the lower deck of the bridge until 1958.

A copy of the front page of a 1920 San Francisco Chronicle.

After multiple seismic studies, a soil investigation program, and even the installation of an earthquake recording system on the floor of the Bay, a preliminary route was selected that would avoid as much bay bedrock as possible. Actually, the route wasn’t that far off from the one Emperor Norton initially proposed. The cost of the project was estimated at $132,720,000 (or about $1.4 billion in 2023 dollars) and was to be financed by toll revenues.

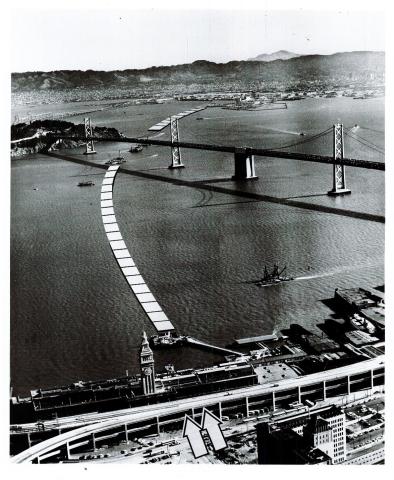

Top image: The route of the Transbay Tube depicted by the square dotted line in a photograph taken during the final stages of construction.

Bottom image: 1967: A concept drawing demonstrating how the Transbay Tube would be deposited on the floor of the Bay.

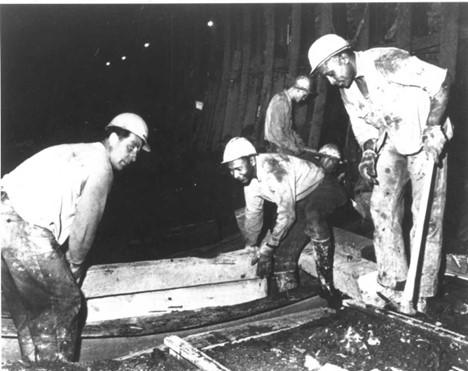

Construction began in 1965 as a joint venture of Peter Kiewit Sons’ Co.; Raymond International, Inc.; Tidewater Construction Corp.; and Healy-Tibbitts Construction Co. Together, they were known as the Trans-Bay Constructors. They kicked things off with a Tube groundbreaking ceremony in 1966 that featured a literal boatload of dignitaries watching a dredge bring up the first of more than 5.7 million cubic yards of Bay mud. It was groundbreaking in every sense of the word.

The contract called for a demanding two-and-a-half-year deadline for completion of the basic structure, so the Trans-Bay Constructors developed a fierce schedule at a pace of building and placing two Tube sections a month. There simply wasn’t time to make mistakes.

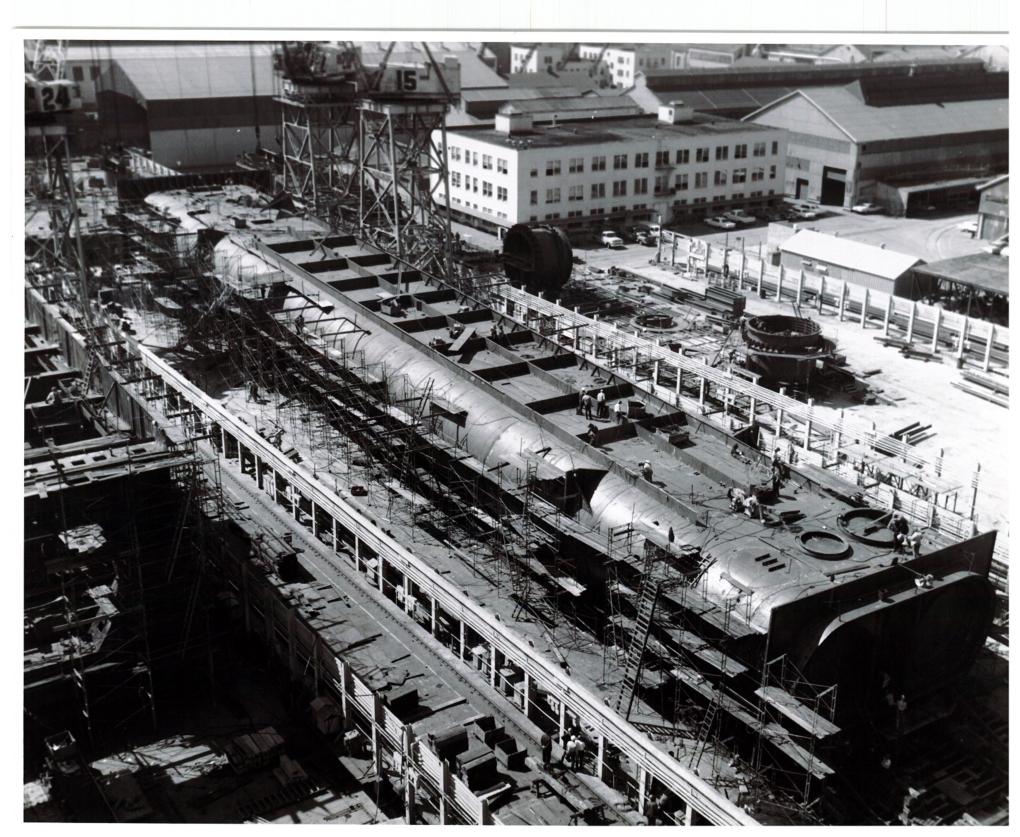

A photo of a section of the Tube under fabrication at Bethlehem Shipyards in South San Francisco.

The Tube is made up of 57 sections, each averaging 330 feet in length. The segments were fabricated at Bethlehem Shipyards in South San Francisco, from which they were launched, towed into the bay, and then sunk into their proper positions.

To get the just barely buoyant segments to the bottom of the bay, each was weighted with 500 tons of gravel ballast. One section weighed approximately 10,000 pounds, about 1/6 of the weight of a BART car. Lowering one segment required a complex system of hydraulic controls and strain gauges that allowed operators to monitor the weight distribution and keep each section level during descent.

Circa 1969: A section of the Transbay Tube being floated into the Bay.

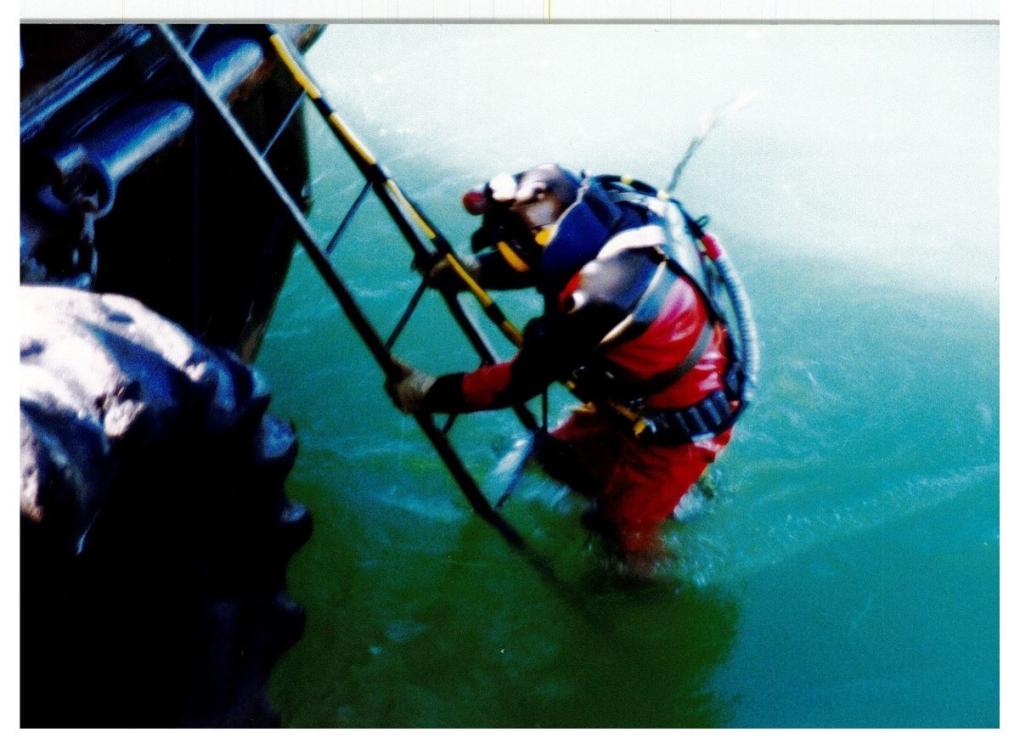

Divers were waiting at the bottom of the bay to direct the segments into exact position. When they surfaced, the divers climbed into two decompression chambers on the barge. It wasn’t 20,000 leagues under the sea, but it was still pretty darn deep.

Concurrently, the trench for the Tube continued to be excavated. About 5.7 million cubic yards of material were removed from the bay. To keep the trench precisely aligned, engineers installed lasers from different shore positions that pinpointed the exact position required for the dredging barges.

In the end, the contractors met their schedule. The last section of the Tube was placed just east of Yerba Buena Island in 1969. Later that year, BART held an open house on both sides of the Bay, inviting members of the public to walk through two sections of the Tube. It was reported that the line to get inside stretched more than a mile.

With the segments in place and any stragglers cleared, the next tasks were laying the track, electrification, and installing the train control equipment and ventilation. The process took about four years, and in August 1973, the first train traveled through the Tube. About a year later, trains were carrying their first passengers across the bay.

Come 1974, the original BART system was officially complete.

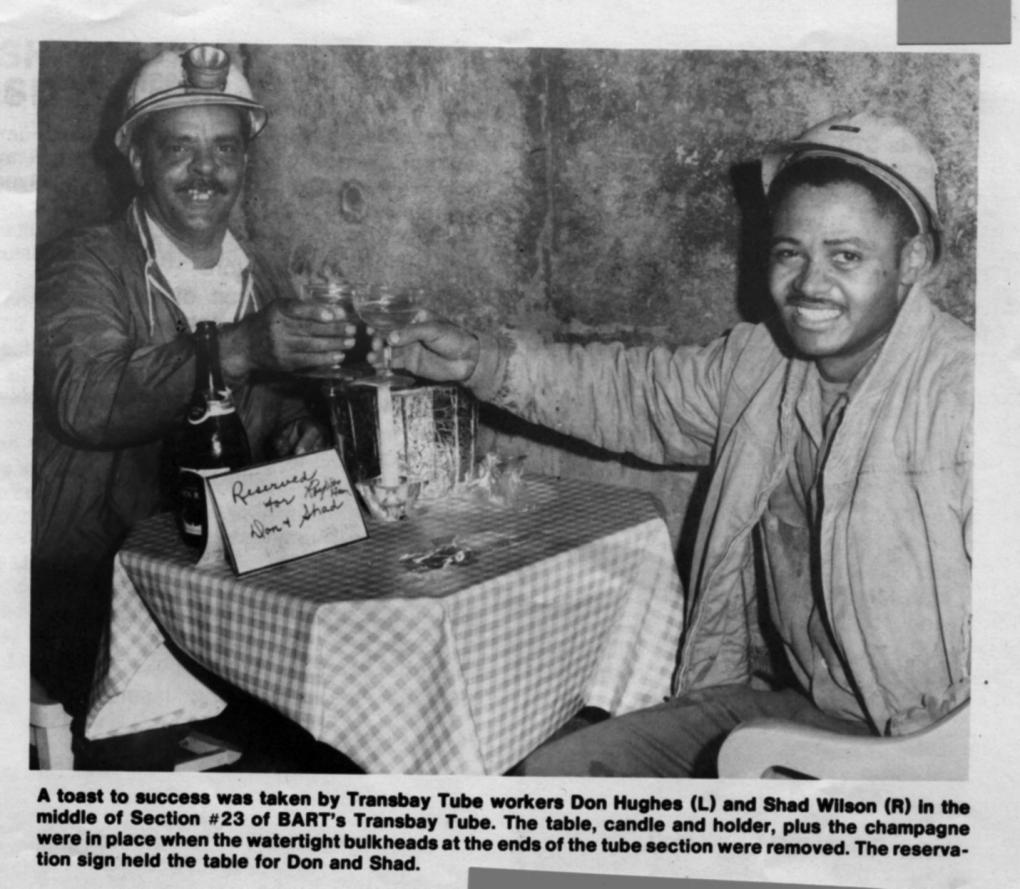

Tube sections were built from both the San Francisco and Oakland sides. When the last bulkhead was removed to finally connect the Tube, workers from the San Francisco side found Oakland-side workers Don Hughes and Shad Wilson enjoying champagne together.

II. Loma Prieta: "BART's Finest Hour"

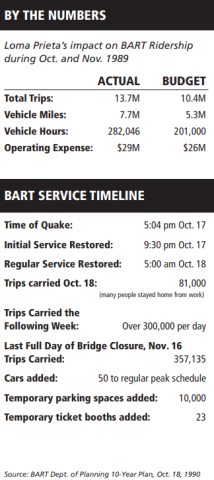

The Tube was just a teenager, barely old enough for a driver’s license, when it was put to a terrifying test. On Oct. 17, 1989, the devastating Loma Prieta earthquake shook the San Francisco Bay Area and Central Coast for eight to 15 seconds, depending on where you were located. Sixty-three people died and 3,757 people were injured. In the aftermath, among other impacts, 12,000 homes and 2,600 business were damaged; the Cypress Street Viaduct on Interstate 880 collapsed; and about 1.4 million people lost power, temporarily knocking radio and tv stations off the air.

Then there was the San Francisco-Oakland Bay Bridge. A 76-foot-by-50-foot section of the upper deck fell onto the lower deck, causing severe damage and one fatality. The bridge is pictured after the earthquake (image courtesy of Flickr).

"There were reports of the bridge being down, flooding and fires in the city, we knew it was serious,” said Frank Wilson, BART General Manager at the time of Loma Prieta, in a 2014 interview with BART. “We thought, 'If the damage was that severe around us, what has BART sustained?' It was all hands-on deck to assess safety and find out how we were going to get back into service."

At the same moment Loma Prieta started shaking the Bay, Donna “Lulu” Wilkinson was operating a train at 80 miles per hour through the Transbay Tube.

“I didn’t even feel it,” she said in a 2014 interview. She was halfway through the Tube when the Operations Control Center gave the order to stop and hold position. Passengers didn’t panic because they were accustomed to short holds in the Tube – standard operating procedure even for minor earthquakes. Most of them didn't notice a thing.

“The Tube absorbed the shock,” Wilson said. “When the engineers and planners first built the system, they were criticized by some from the outside that it was too expensive and unnecessary. But how much is a life worth? How much was it worth to keep people moving between Oakland and San Francisco?”

Calls began flooding into the Operations Control Center from employees asking for earthquake assignments, while those on the job gathered their wits and began inspecting the system from top to bottom for damage. Incredibly, damage was minimal, and less than 12 hours after the earthquake hit, BART service resumed.

Loma Prieta and the weeks that followed are often referred to as “BART’s finest hour,” and with good reason. Staff quickly jumped to take on extra shifts so BART could run 24-hour service in the Transbay Tube, which started the day of the earthquake and ended December 3. The Bay Bridge did not reopen until November 18.

Said Wilson: “Not only did they get BART back on track, they kept it there for more than a month while the Bay Bridge was out of service, carrying more than 10 million passengers to their jobs and homes around the clock.”

III. The Earthquake Retrofit: “Like doing open heart surgery every night then bringing your patient back to life, over and over and over again”

A diagram of the Transbay Tube that shows the outer steel shell, concrete liner, and steel plates that line the Tube’s interior.

Loma Prieta had a magnitude of 6.9. What would happen to the Tube in the event of a once-in-a-thousand-years earthquake?

This was the thought rumbling around the mind of Jim Dunn, BART’s then-Chief Engineer, when he instigated what became known as BART’s Earthquake Safety Program (ESP) in the early 2000s. The huge project was officially completed this year.

“Dunn knew Loma Prieta was not the worst-case scenario. He wanted to know if a real big one would give us a problem,” said Tom Horton, who was BART Group Manager of ESP before retiring in 2017.

With ESP, BART was not just preparing for a major earthquake, but one that might be centered closer to the core system, which runs directly adjacent to the San Andreas and Hayward faults.

On November 2, 2004, voters in Contra Costa, San Francisco, and Alameda counties approved Measure AA, which allowed BART to issue general obligation bonds to fund up to $980 million of the $1.4 billion total cost of earthquake safety improvements. The team hit the ground running. The Tube retrofit began years later, in 2017.

“We started with a major evaluation of the system and how vulnerable it was to earthquakes,” Horton said. When Horton started, he had three employees. At the height of the project, more than 100 people were working on the program, 30 of whom were devoted to ESP full-time.

“I have immense respect and appreciation for the personnel who worked on this,” said Zach Amare, BART Assistant Chief, Infrastructure Delivery. Nearly every department at BART had a role to play, including but not limited to the Operations Control Center, Traction Power, Track Maintenance, System Safety, Power/Mechanical Engineering and Maintenance, Operations Planning, Locomotive Operators, Operations Liaisons, Government and Community Relations, Communications, and many, many more.

He credits the project’s success to four things: dedicated BART personnel; executive management who offered full support from the get-go; skilled contract personnel “who were up for the challenge to solve problems”; and a cohesive project management team.

“Without these elements, this complicated, challenging project would not have been successful,” Amare said.

Chuck Bernardo, BART Group Manager of Capital Projects, said he “didn’t realize how one-of-a-kind the Tube was until I started working on it.”

“The challenge of the retrofit appealed to me,” he said. “You’re working at night and running the system the rest of the time. It was like doing open heart surgery every night then bringing your patient back to life, over and over and over again. You had to just dive right in. No one could tell you how to do it."

A key piece of the Earthquake Safety Project was the seismic retrofit of the Transbay Tube, deemed BART’s most valuable asset.

“It was the most difficult engineering project I have worked on with many unexpected challenges along the way, both in design and construction,” said Mark Salmon, who helped coordinate the retrofit design work for BART. "It really showed me the power of teamwork and perseverance. In many respects the Tube is unique in the world; there is no other similar example we could use to draw experience from and guide us. We had to solve the design and construction problems ourselves.”

We want to be very clear: The Transbay Tube is structurally sound, but we are preparing for a rare and devastating earthquake, defined as something that happens once every thousand years. In an event this large, the Tube won’t fail, but it could crack and leak.

“Underground structures in general are less of an issue because they don't see the same level of ground motion as the surface,” Horton said. “The wave is confined by the soil if it’s underground, but when it hits the surface, you get big movements.” As evidenced by the Tube travelers during Loma Prieta, the Tube may be one of the safer places to be during a big quake.

BART worked with earthquake retrofit specialists using a combination of geotechnical and structural site investigations, computer simulations, and testing of materials and models to develop the retrofit design.

Part of the modeling process including traveling to UC Davis, which has an old NASA centrifuge once used to train astronauts. Now, researchers use the centrifuge to simulate the pressures earthquakes could apply to buildings, and in our case, the pressures the Tube might face in a major shaker.

Back in the 1960s, engineers designed the Tube to flex with earthquake ground motions to dissipate earthquake forces and absorb shock. A stiff Tube would become brittle and break in an earthquake, so the “Tube wiggle” is crucial.

An image of one of three locomotives on the work train used during the Transbay Tube retrofit.

At both ends of the Tube, there are giant seismic joints that allow the two ends of the Tube to move independently without damaging the structure. During the retrofit, the original joints were modified to increase their movement capacity. Now, the two sides can “separate” further without major damage to the Tube.

On the Oakland side of the Tube, a steel liner was added to withstand the expected large forces this area could experience in an earthquake. The steel liner is both a structural fix and a means of preventing leakage.

"There could be flooding in the Tube due to a 1,000-year earthquake, but it would be slow enough that people could get out safely,” Horton said. As it turns out, the Tube is predicted to sustain very little damage in a 500-year earthquake event.

BART engineers addressed the potential for leakage after a severe earthquake with two elements. The first was to install the steel inner liner in the sections most likely to experience the largest movements. The second was an upgrade to the Tube’s pumping system to enable it to handle a higher volume of water and pump at a greater rate.

The steel plate handling machine deserves some special attention as it was crucial to the project.

The machine, transported into the Tube by a specialized work train (more on that below), placed steel plates fabricated to match the Tubes arched geometry. Once secured by concrete anchors, they were welded together. Grout was then used to fill the void between the existing concrete liner and new steel liner. A different method utilizing a plastic sheet membrane was employed on the Tube section supporting the trackway.

During the retrofit, every minute was precious. When Horton visited the steel liner operation during a work night, he said it ran “like a military exercise.”

"As soon as the work train arrived, workers got off and went right to work, each person knowing exactly what their job was and going right at it.”

Some workers put in 12-hour shifts, six days a week, to get the work done. This dedicated cohort includes Frank Greco, BART Structures Equipment Operator, who was one of the operators of the 800-foot, custom-built locomotive train.

“Working those long hours was a sacrifice, for sure,” Greco said. “But I felt like I was a part of something bigger than myself. The Tube is such a big part of BART. It’s something thousands of people travel through on a weekly basis. Just to be a part of that, I felt very fortunate.”

Greco said community sprung up around the painstaking work and the hundreds of hours they spent underwater. Often, the community was motivated by food. BART Operations Supervisor Harold Stuart would make regular Costco runs and bring giant boxes of snacks into the Tube for the workers. As Kenny Meyers said in the first half of this story, there’s no Starbucks down there.

Greco said his first trip into the Tube made him "trip out.”

“I loved it,” he said. “You’re in the middle of the water! It’s crazy! It’s unreal!”

A photo of the completed retrofit inside the Tube.

Most of the time, Greco tried not to think about how deep underwater he was on those long graveyard shifts. It’s easy to psych yourself out down there, he said.

Will Sowell, Jr., BART Structures Equipment Operator, also served as a work train operator, and initially, he didn’t want to do it.

Sowell was used to big equipment, but not that big. The closest thing to the work train he’d operated was a power flat machine.

He and other work train operators received specialized training to operate the work train, which can hold up to three 50-foot-long flatcars, seven 40-foot-long flatcars, two 41-foot-long concrete cars, one 55-foot-long steel plate handling device, and one 40-foot-long plate handling device flatcar. Say that five times fast.

"The first time being on that machine was scary,” Greco said of the work train. “You know what you’re doing, but when you throw in the train with a lot of power and a braking system that’s intricate, it is a lot to handle.”

Greco said he got used to it quickly. “And at the end of the day, not a lot of people can say they’ve operated a huge train with 17 cars. That’s something to put on your resume for sure.”

Getting the job done in such a tight timeline took serious coordination and logistics.

Bernardo said the Contractor would work backwards to build each night’s work schedule. They had to ask questions like: How much concrete do I need? How many steel plates have to go up? How many anchors and ties do we bring?

“The project team and contractor were constantly thinking about how to work under the constraints of the Tube, Bernardo said. “As we worked backwards, we’d realize, oh, we can’t do this task because this is in the way. Then, if we remove that first task, we have to find a place to put it back in.”

Sowell witnessed these logistics in real-time. Every night before leaving the Oakland Yard, Sowell and his team would go through an extensive safety and supply check for the work train to make sure they had everything they needed, the cars were in the right order, all the equipment was secure, and the brakes, horns, bells, whistles, etc., were working properly. Then Operations Control Center would give the cue for the train to head out. Since work began at 9pm, passenger trains would share the tracks with the work train as it made its way underwater.

"Every aspect of this project was unique because the Tube is unique,” Horton said. There's just nothing quite like our Tube.

IV. BART’s Cathodic Protection System: “Without this system, the Tube would be gone by now”

The Transbay Tube is an underwater steel structure, meaning it is prone to rust. To extend the life of the tube, BART employs a cathodic protection system, which prevents this from happening using electrochemistry.

For BART's cathodic protection system, an external power source is used to push current from the anode sleds (an old, rusted anode is pictured in the first photo in the above slideshow) to the steel structure of the Tube, which acts as a cathode. The anode sleds sacrifice themselves (i.e. rust) to protect the cathode -- in our case the steel structure of the Tube.

There are a total of 30 400-pound anode sleds on the Tube, each containing16 anodes apiece. A huge wire connects the anodes to a power box contained within the Tube, which pumps 200 amps of current -- that's equivalent to the energy needed to power an entire modern home!

“Without this, the Tube would be rusted by now and require billions in replacement costs,” said Senior Manager of Engineering Programs Maansii Chirag Sheth, who oversees the cathodic protection system. And don’t worry about the marine life, she stressed. “If you’re a little fishy and you touch the Tube, you won’t feel the current. It’s not an electric current that’ll shock you.”

Maansii is one of just a handful of certified cathodic protection engineers in the U.S. The work is extremely specialized, and corrosion engineers must take a difficult certification test. Maansii passed the test in 2013. She was just the 39th person in California to receive the specialized certification.

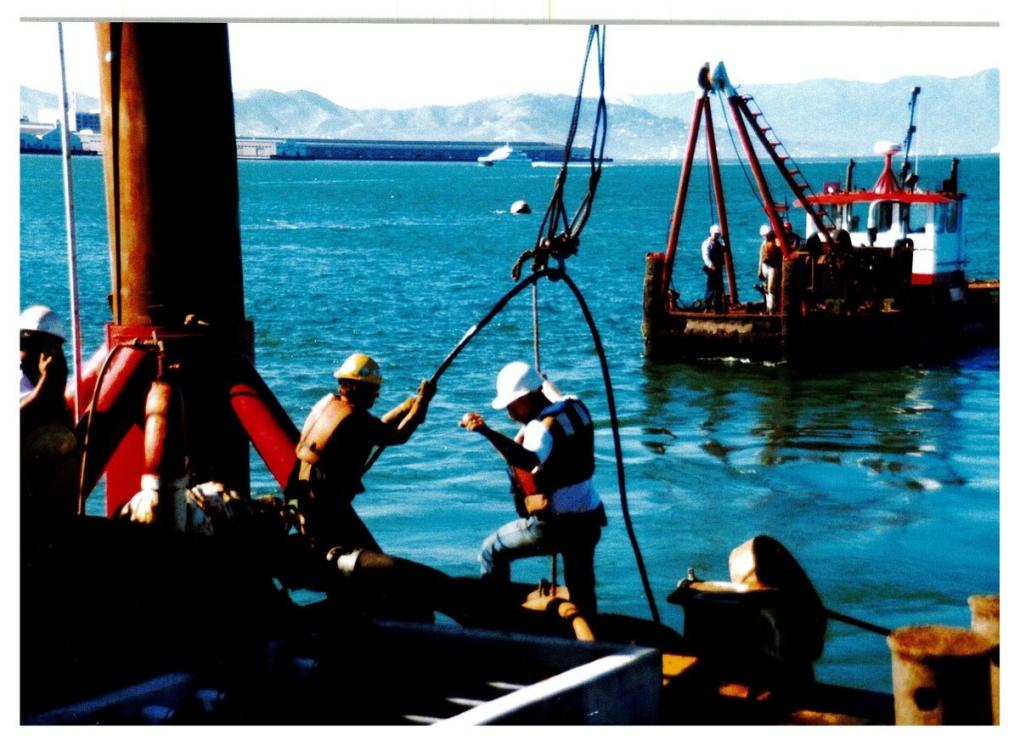

Large clamshell dredging bucket being lowered into the bay as part of soil handling operations.

Every few years, the rusted anodes must be replaced, and only a handful of contractors in the U.S. are equipped for this sort of specialized, largescale work, Maansii said.

Replacing a 400-pound anode attached to a Tube more than 100 feet deep in zero-visibility waters is a tall task, as you can imagine. Best-case scenario, the replacement of a single anode takes about a half a month. With shifting currents and wind, the anodes can move slightly, and down there, you can’t see a thing. The work is faster now that GPS systems have improved, which make it easier to locate the anode in the water.

“It’s a complex operation with a large amount of variables at play. You have to account for weather and seasons, contracting and securing a barge, hiring trained divers, leveraging specialized equipment, and obtaining permissions from the Coast Guard, and so on," Maansi said.

Diver stepping off barge into the Bay as part of cable installation operations near the Transbay Tube.

You also can’t work when it’s stormy or during certain months, including the entirety of Dungeness crab season. One must manage tide cycles, passing vessels, soil handling restrictions – the list goes on.

Once all that’s taken care of, it’s time to get down to work. First, a large clamshell bucket on the barge digs out a bunch of mud to expose the anode. Deep-sea divers specially trained for industrial projects pinpoint the exact location of the anode, which is detached then lifted from the water onto the barge. Then, the new anode is lowered down and attached to the cable system. After testing, the anode is energized, and its sacrificial work begins.

Let us all take a moment to thank the sacrificial anodes for their service. Without them, no Tube would be there and no connectivity in the Bay.

V. The Transbay Tube’s Next Chapter: “It could be under the Bay forever”

Though this story is coming to an end, the story of the Tube is far from over. The Tube is fifty, true, but we can’t say it’s hit middle age just yet.

Thanks to the Earthquake Safety Program, those sacrificial anodes, and the many BART staff who work to keep it maintained, the Tube’s got quite a life ahead of it.

What might the future hold? Currently, BART is working on a project that will allow us to operate up to 30 ten-car trains per hour in each direction through the Tube, increasing capacity and shortening wait times at stations. Currently, a maximum of 24 trains per hour can travel through the Tube in each direction.

The program includes four elements: the purchase of additional railcars, a new railcar storage yard at the Hayward Maintenance Complex, a new communications-based train control system that will allow shorter waits between trains, and five additional traction power substations to provide the additional power needed for more frequent service.

It’s a bright future for a structure with a history long enough to fill the pages of a whole book. We’ll save that project for another day.

“Nobody has a Tube like ours,” said Horton in conclusion. “It could be under the Bay forever. That gives you something to think about.”